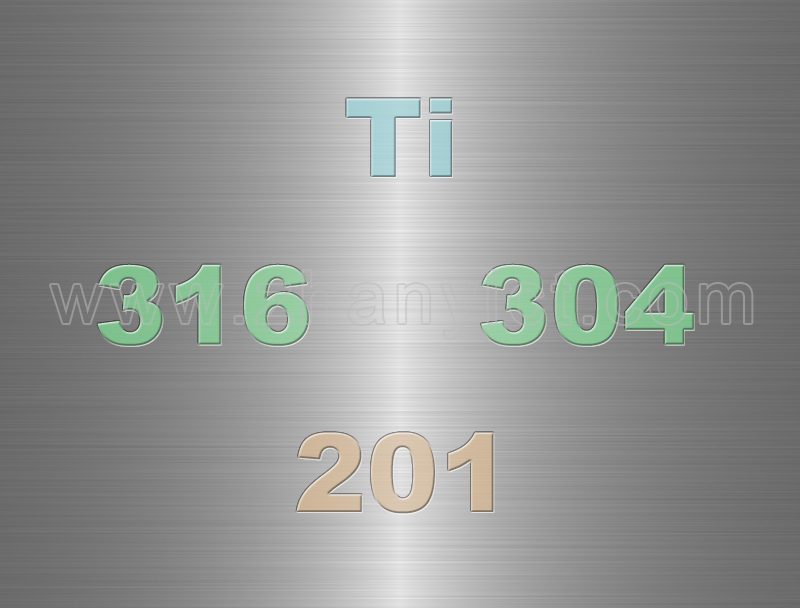

What Are the Material Options for Insulated Cups? - An In-Depth Analysis of 201, 304, 316 Stainless Steel and Titanium

There's a story in every cup, and warmth in every life. Hello everyone, welcome to "Dong Dong's Cup Talk" In the manufacturing of insulated cups, material selection directly impacts product safety, durability, and market competitiveness. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlCurrently, the market is flooded with insulated cups made from various materials, with stainless steel dominating the mainstream and titanium representing the high-end segment. Today, we'll delve into the material selection for insulated cups from an engineering perspective.

I. Ideal Material Choices for Stainless Steel Insulated Cups

Food-grade stainless steel is the preferred material for insulated cup manufacturing, with 304 stainless steel (06Cr19Ni10) being the optimal choice. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlThis austenitic stainless steel contains 18-20% chromium and 8-10.5% nickel, offering excellent corrosion resistance and formability. Its corrosion resistance stems from a dense chromium oxide protective film that effectively resists corrosive agents in daily use.

316 stainless steel (0Cr17Ni12Mo2) is a higher-end option, adding 2-3% molybdenum to 304's composition, http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlfurther enhancing corrosion resistance—particularly against pitting in chloride-rich environments. This material is better suited for storing acidic or salty liquids.

II. The Reality and Risks of Using 201 Stainless Steel

201 stainless steel (1Cr17Mn6Ni5N) is a nickel-saving alternative, replacing some nickel with manganese and nitrogen. While this reduces costs, it significantly compromises corrosion resistance.http://www.zhanyict.com/en/ProductsDetail-VB-10486.html In real-world use, 201 stainless steel is prone to rusting, especially when containing acidic beverages, potentially leaching harmful elements like manganese.

Despite these drawbacks, many manufacturers still use 201 stainless steel due to its cost advantage—it's only 60-70% the price of 304. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlSome even mask material flaws with surface treatments to compete on price, harming consumer rights and industry health.

III. Material Properties of Titanium Insulated Cups

Titanium cups typically use pure titanium (Gr2) or titanium alloys (e.g., Ti-6Al-4V). Pure titanium boasts exceptional biocompatibility and corrosion resistance, with a density of just 4.51g/cm³ (60% of stainless steel) yet comparable strength. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlIts naturally forming titanium oxide film is dense and stable, resisting various corrosive agents.

However, titanium costs 5-8 times more than 304 and 3-5 times more than 316, due to difficult smelting and high processing requirements. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlStill, titanium’s lightweight nature and premium texture make it competitive in high-end markets.

IV. Comparing the Processing Performance of Stainless Steel vs. Titanium

Stainless steel holds clear advantages in manufacturing:

- Excellent ductility, http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlallowing mature stamping and welding processes.

- Higher production efficiency and lower costs.

Titanium, meanwhile, poses challenges:

- Low thermal conductivity, leading to work hardening.

- High chemical reactivity at high temperatures,http://www.zhanyict.com/en/ProductsDetail-VB-10486.html requiring protective atmosphere welding.

- Complex surface treatment processes.

Production costs for titanium cups are 3-5 times higher than stainless steel, mainly due to material and processing expenses. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlHowever, titanium’s lightweight nature reduces shipping costs, and its high added value justifies the premium.

Conclusion

Material selection is central to insulated cup manufacturing.http://www.zhanyict.com/en/ProductsDetail-VB-10486.html From a professional standpoint:

- 304 stainless steel offers the best balance.

- 316 stainless steel suits specialized needs.

- Titanium targets the luxury market.

- 201 stainless steel reflects industry malpractice and requires stricter regulation.

Looking ahead, advancements in titanium processing may lower costs, potentially making it a more accessible choice. http://www.zhanyict.com/en/ProductsDetail-VB-10486.htmlFor now, informed selection ensures quality, safety, and market success.

(Note: Technical details are simplified for readability while maintaining accuracy. Adjust tone as needed for target audiences.)

Dongguan Zhanyi Commodity Technology Co., Ltd. specializes in the production of metal cups, plastic cups, coffee cups, suction mug, lunch boxes, food jar, travel mugs, portable water bottles, sports bottles, home life desktop trash cans, thermos bottles, etc.These products are all our annual exports, and are recognized and loved by the US, Europe, Australia, Japan, South Korea, Taiwan, Hong Kong and other consumers. Support for small quantity order, fast customization.