Comprehensive Guide to Stainless Steel Water Bottle Surface Coating Processes (Automation Equipment Chapter)

"A cup holds stories, life carries warmth." Hello everyone, welcome back to "Dong Dong's Cup Talk" Having shared various water bottle-related topics, today we'll explore surface coating processes again. To present this complex subject clearly, we've invited Mr. Liao from our long-term coating partner company. With his decades of hands-on experience and management expertise, he'll explain different stainless steel water bottle coating techniques and their distinctions. http://www.zhanyict.com/en/ProductsDetail-VB-10507.htmlThe following content reflects Mr. Liao's professional perspective, and due to its depth, we'll present it in multiple installments.

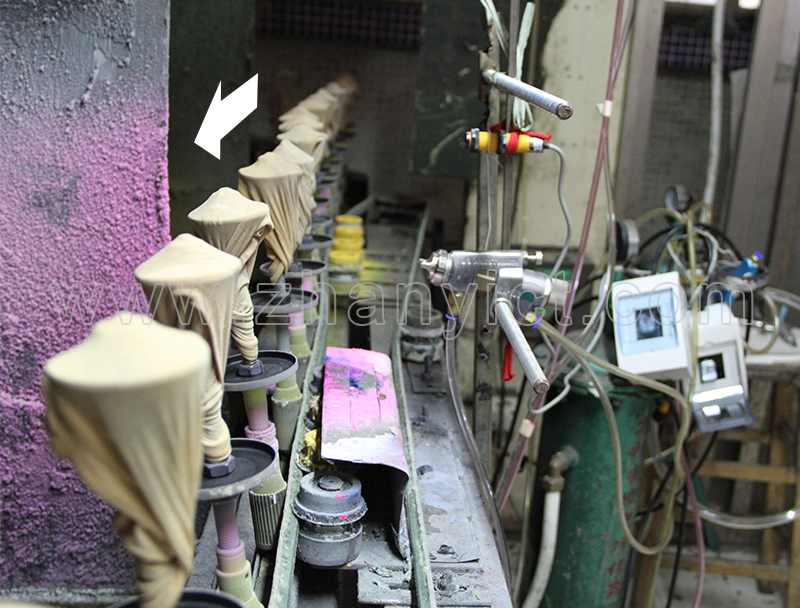

In modern coating facilities, application methods primarily divide into manual spraying and automated spraying. Manual spraying typically serves small-batch production or prototyping, while automated systems handle mass production with superior efficiency and consistency. Different factories employ automated lines tailored to their specific product specializations.

The hanger spacing in overhead conveyor systems critically impacts coating efficiency. Our CFD simulations revealed that when spacing falls below 15cm, powder deposition rates at bottle openings decrease by 23%. http://www.zhanyict.com/en/ProductsDetail-VB-10507.htmlWhile floor-mounted roller conveyors save space, they inevitably create 3-5mm coating blind spots where bottles contact the rollers.

A notable case involved a US manufacturer facing returns due to exposed metal at bottle bases. Our solution transformed their overhead line with a "planetary rotation system," enabling three-dimensional spinning during transit. http://www.zhanyict.com/en/ProductsDetail-VB-10507.htmlThis innovation reduced dead zones below 0.5mm², though requiring a 180,000 RMB equipment upgrade. The modification successfully resolved their quality issues while demonstrating how strategic automation investments can solve persistent production challenges.

There are stories in the cup, and life has warmth. Use the right cup and choose the right factory. We have dozens of patented cup and pot products and provide OEM services to the world. We have dozens of professional engineers who provide cup and pot product development services to the world. We have multiple complete current cup and pot product production lines to provide OEM services to the world. Dongguan Zhan Yi Commodity Technology Co.,Ltd. attaches great importance to contracts and quality. We welcome global merchants to conduct on-site factory inspections and in-depth cooperation.